Thank you for visiting Hitachi Global Air Power at ComVac. Our global product portfolio features compressed air solutions engineered for Reliability, Durability and Performance.

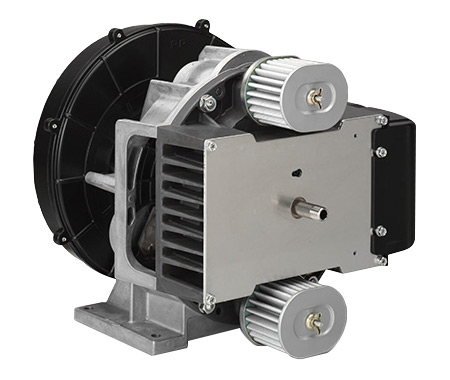

Oil Free

Gas Compression

Vaopr Recovery

Drill Compressor Kits

Scroll

Oil Free Rotary Screw

Single-Stage

Two-Stage

Hitachi will resolve environmental issues and achieve both a higher quality of life and a sustainable society through its Social Innovation Business in collaborative creation with its stakeholders.

Use the checkboxes to select the types of cookies you want to accept, then press the “Save Settings” button. View our Privacy Policy.